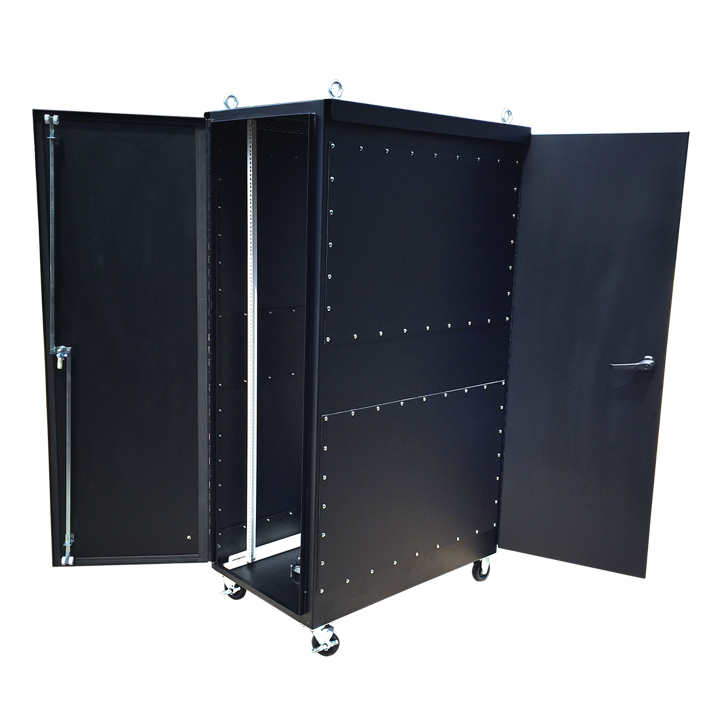

For most people, it seems that enclosures are not considered vital at any processes. But enclosures are carefully engineered to protect electrical equipment in certain applications and processes. The industries that needed these enclosures are telecommunications, IT systems, water treatment plants and marine offshore companies.

Our time today is fast-changing, with the recent innovations and technologies engineers are coming up with important solutions to business processing and operations’ common problems. The right enclosures on different types of applications are mostly important – not only it can make the operations and processes efficient, it can save thousands of lives and it can make certain processes and operations cost-efficient.

However, this imposes a great challenge for design engineers. They should determine which enclosure is right for different applications. Nowadays, enclosures can come in many different types and designs and they can provide a certain level of degree of protection to electrical equipment.

On the operating managers’ side, they should have the proper knowledge on which electrical enclosures they should buy or manufacture for specific applications. In this article, we will discuss the widely used NEMA enclosures and what are their different uses.

DIFFERENT NEMA ENCLOSURES

For proper discussion, the different types of enclosures are referring to the standards set by the National Electrical Manufacturers Association (NEMA), and their different features and uses.

NEMA is the organization which defines the North American standards for electrical enclosures. To improve the safety and reliability of their products, most manufacturers in the United States design their enclosures to meet these standards.

The National Electrical Manufacturers Association is the defining body located in USA set the standards and different types of electrical enclosures in Northern America. To provide the companies and the engineers with the safety standards for manufacturing enclosures, companies are complying with the set of regulations NEMA has set.

WHAT NEMA RATINGS ARE FOR?

NEMA ratings identify the capability of the enclosure to withstand certain degree of environmental hazards and their capabilities & features. It also determines in which what type of material should be used in making these enclosures. These standards enable the engineers to choose the right enclosures for specific needs.

Below, we’ll discuss the most popular NEMA rated electrical enclosures and the critical role they play to ensure product function and safety.

To further explain this, a utility company that would like to have their sensitive equipment be protected from harsh environmental factors may choose to have NEMA 4X enclosure. NEMA 4X can protect their equipment from corrosion because of salt water and possible water ingress.

NEMA 1 ELECTRICAL ENCLOSURES

This enclosure is engineered for indoor uses or applications and amongst all NEMA types this one provides the least amount of protection for enclosures. This enclosure can protect any electrical equipment from dust or dirt ingress, or protect the personnel from accidental contact with any equipment.

Although they have limited protection, they are widely used for certain applications. Companies use NEMA 1 enclosure to protect indoor electrical equipment, one of which is the variable-frequency drives installed indoors.

CONSIDERATIONS FOR NEMA 1 ENCLOSURE

If NEMA 1 is installed in environments where there is no presence of hazardous chemicals or combustible fluids, this enclosure is the cost-effective way to protect your electrical equipment. It can also prevent accidental access from personnel who use this equipment. However, engineers who are concerned about moisture seeping through the enclosure may want to consider using NEMA 2 instead. It offers an additional layer of protection against the lightest water ingress.

Additionally, the heat generated by the equipment inside the enclosure should also be considered. In IT companies where there are data centers or networking equipment, there is a possibility of equipment overheating because of heat load. It can cause damage and hinder certain processes or operations.